Customer and Goal

An industry-leading recreational vehicle manufacturer builds travel trailers, fifth wheels and toy haulers. They strive to provide high-quality RVs and to retain customers for life. In addition to crafting personal connections with customers, the company prioritizes value and luxury with each RV product.

The Challenge: Failing Wear Bars and Screws

The RV manufacturer builds campers with slide-outs to ensure customers have the option to extend their square footage for bonus living space, if desired. The slide-out moves between extended and retracted positions. Unfortunately, the industry has long faced persistent challenges related to camper seals that properly seal the slide room floor.

Traditionally, the wear bar is mounted on the main floor and secured with screws at a 45-degree angle. This sharp angle, coupled with the weight and movement of the wear bar over time, results in failures to the screws and, ultimately, the wear bar.

In addition to the wear bar issues, the RV manufacturer wanted a way to block the daylight that enters the RV through an open space around the slide-out bottom pan. The open space also allowed leaks and moisture to enter the vehicle.

The Solution: A Flush-Floor Slide-Out with TPE and TPO

After talking to several other sources who couldn’t solve the slide-out challenges, the RV manufacturer found a capable partner in Trim-Lok. Thanks to Trim-Lok’s market expertise, engineering knowledge and relationships within the RV industry, our team was uniquely positioned to assist the manufacturer with a reliable RV slide-out seal solution.

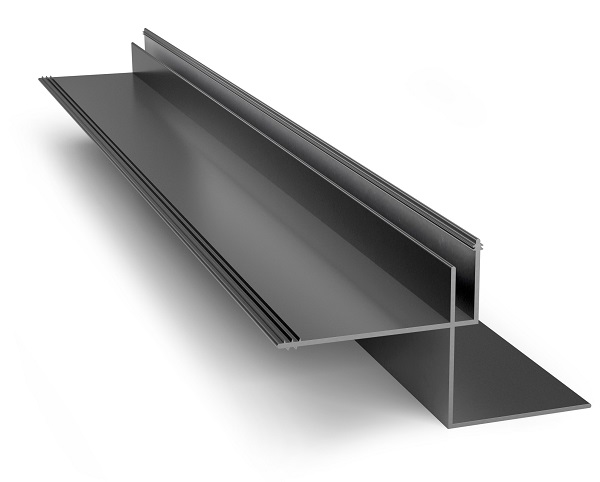

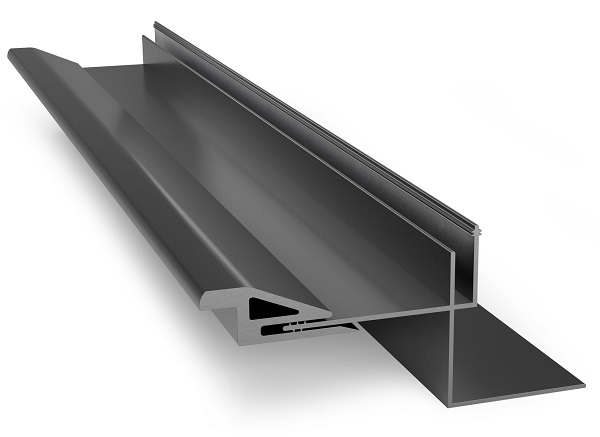

The Trim-Lok team considered the manufacturer’s design requirements, ideas and timeline. They carefully examined how the slide-out moves over the axel of the trailer and how the slide room falls down into the groove of the floor, leaving the wear bar vulnerable to failure and exposure to the elements. By creating a newly designed flush-floor slide-out using TPE and TPO, Trim-Lok met the requirements and crafted a more functional, cost-effective RV seal.

Trim-Lok engineers met dozens of times with the RV manufacturer’s team members to fulfill the RV slide-out bottom seal request and to bring the first variation of the prototype to life. After three prototype variations over five months, the Trim-Lok team produced and shipped the final slide-out bottom pan with integrated wear bar.

Increased Wear Bar Support

Trim-Lok took the existing design, integrated the wear bar, and extended the leg flap off the back side. Our engineers also crafted a tongue-and-groove middle section that slides into the integrated wear bar. This provides more support and the sliding function reduces the SKUs from six to two—which ultimately helps the RV manufacturer deal with fewer suppliers and reduce costs.

Optimized Screw Placement

To improve the quality of the install and ensure a longer lasting wear bar, Trim-Lok redesigned the point where the screws secure the wear bar to the main floor. Instead of securing at a 45-degree angle, the screws now secure perpendicular to the floor. This relieves tension and improves the way the slide room runs across the floor. With this redesign, the wear bar is easier to remove for servicing and repairs.

Blocked Daylight

The perpendicular nature of the screws also helps improve the slide-out room’s insulation. It seals off the bottom of the slide-out and covers the rollers to provide better sealing and aesthetics. With the new RV slide-out gasket, the slide-out room won’t leak or allow moisture or daylight to enter the slide-out, creating a more comfortable living space for travelers.

The Result: Easier Installs, Inventories and Purchases

Partnering with Trim-Lok helped the RV manufacturer achieve all its design requirements for an overhauled flush-floor bottom pan with integrated wear bar. Not only does the new slide-out bottom pan improve the quality, longevity and functionality of the RV part, it also reduces the number of SKUs from six to two, helping the manufacturer cut costs and decrease the complexity of the supply chain. The slide-out seal is easier to install, purchase, inventory and cycle count—and the RV manufacturer is pleased with the outcome.

Custom Capabilities

Trim-Lok’s engineers and designers leverage decades of industry expertise and material knowledge to create custom products that solve any problem. We utilize rapid prototyping, on-site machinery and cost efficient shipping from our convenient West Coast and Midwest locations. With extensive custom capabilities, we are ready to help you personalize trims and seals.

Interested in other RV slide-out room seals? Find a sales rep near you, and we will work with you to customize a product for your application.

FIND A SALES REP