Flexible Edge Trim Applications

The right plastic edge trim for metal edges can impact any project. Whether you run an auto repair shop and need trim for cars and trucks, or manufacture furniture for a living and require decorative trim for your line of products, you need quality vinyl edge trim that gets the job done.

Our edge trim is ideal for many applications, including:

With its strong gripping power, Trim-Lok’s plastic trim molding resists the effects of sunlight, water, and the ozone. Order our custom plastic extrusion in a variety of sizes to meet your unique project needs—no matter the size or complexity.

Customize Your Flexible Edge Trim with Our Product Builder

You're in control with Trim-Lok’s edge trim product builder. Our edge trim thicknesses range from 1/8 inch" to 3/4 inch” (3mm to 19mm), so you can easily custom order the size you need based on your exact specifications. As an added bonus, we manufacture each vinyl plastic edge trim with individual internal metal clips and either a single gripping tongue or a dual gripping tongue. These clips and tongue provide a stronger grip to ensure our edge trim products last longer than many alternatives available on the market.

Simply choose the size and quantity you need. Then, add the flexible molding trim to your shopping cart. With excellent customer service and quick, reliable shipping, you’ll have your brand-new, flexible edge trim in your hands before you know it.

Ready to get started? Build your own PVC edging trim today and see the difference for yourself.

Contact a Sales Representative Today

| Description |

Trim-Lok’s Edge Trim is comprised of flexible Poly Vinyl Chloride (PVC) trim with individual

internal metal clips and a gripping tongues to provide a stronger griphold. Plastic edge trim is used in a variety of industries and for numerous applications, such as automotive, marine and boating, machinery and manufacturing, and much more.

|

| Resistance to |

- Ozone – Excellent

- Water Absorption – Excellent

- Sunlight Aging – Excellent

- Low Temperature – Good

|

| General Temperature Rating |

-20ºF. to +158ºF. | -29ºC. to +70ºC.

|

| Outer Coating Material |

Poly Vinyl Chloride (PVC) 85 Durometer Shore A |

| Internal Metal Clip Materials |

- Aluminum – 3004 H38P

- Steel – CRS SAE 1010, Rockwell B ,75-85 Durometer

|

Flammability &

Code Compliance |

- FMVSS 302 Horizontal Burn

- FAA/FAR 23.853

- UL50

- UL844

- ROHS Compliance

|

| View Edge Trim Spec Sheet |

| Edge Thickness |

62 Series |

100 Series |

1375 Series |

200 Series |

75 Series |

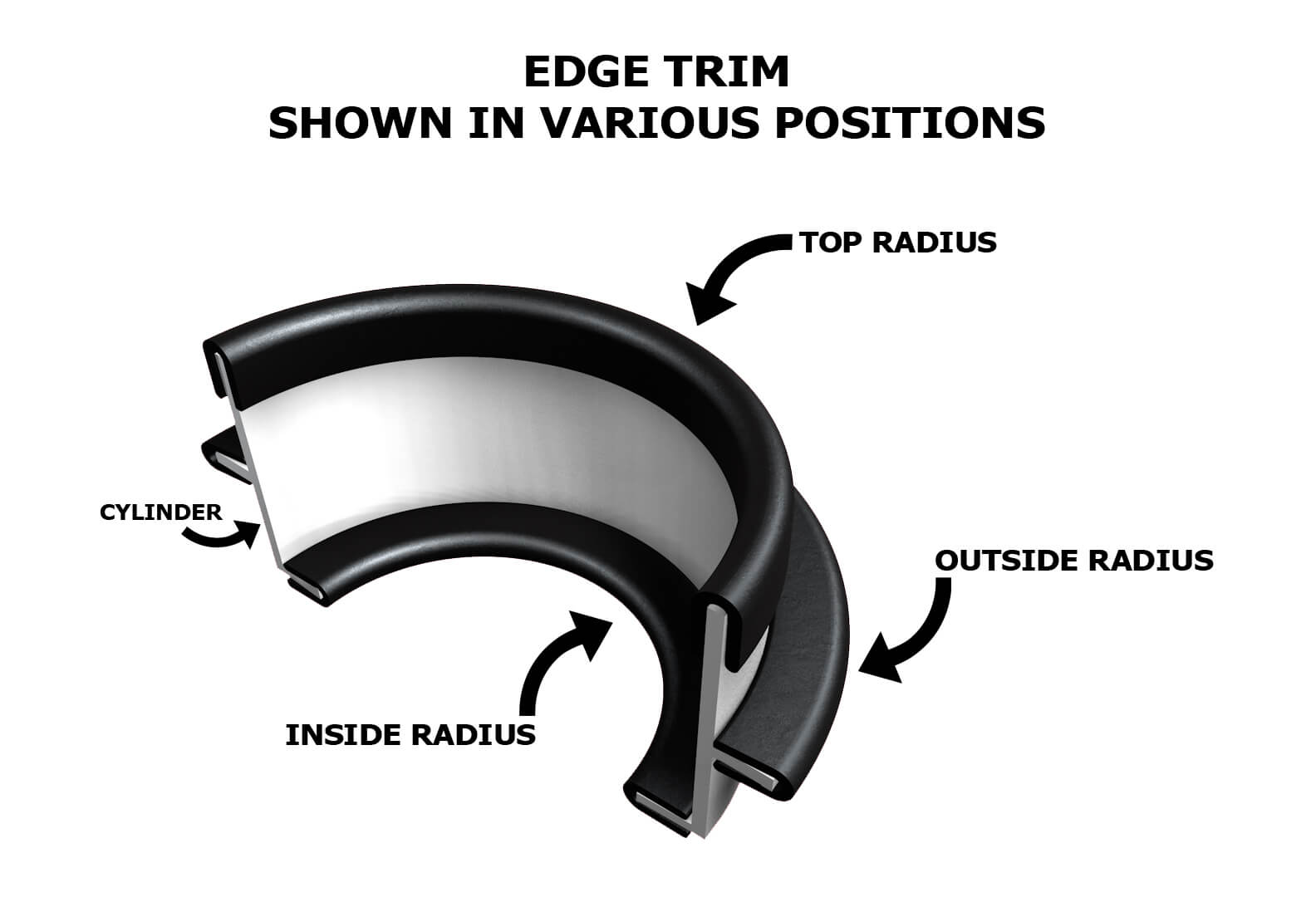

| | Top |

Inside |

Outside |

Top |

In. |

Out. |

Top |

In. |

Out. |

Top |

In. |

Out. |

Top |

In. |

Out. |

1/64"

(.40 mm) |

0.75

(19.05) |

0.75

(19.05)

|

0.75

(19.05)

|

|

|

|

|

|

|

|

|

|

0.75

(19.05)

|

1.50

(38.1)

|

1.50

(38.1)

|

1/32"

(.79 mm) |

0.75

(19.05)

|

0.75

(19.05)

|

0.75

(19.05)

|

0.75

(19.05)

|

1.50

(38.1) |

1.50

(38.1)

|

|

|

|

|

|

|

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

1/16"

(1.59 mm) |

0.75

(19.05)

|

0.75

(19.05)

|

0.75

(19.05)

|

0.75

(19.05)

|

1.00

(25.4) |

1.50

(38.1)

|

0.75

(19.05)

|

1.50

(38.1)

|

2.00

(50.8) |

0.75

(19.05)

|

1.50

(38.1)

|

2.00

(50.8) |

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

5/64"

(1.98 mm) |

0.75

(19.05)

|

0.75

(19.05)

|

0.75

(19.05)

|

|

|

|

|

|

|

|

|

|

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

3/32"

(2.38 mm) |

0.75

(19.05)

|

0.75

(19.05)

|

0.75

(19.05)

|

0.75

(19.05)

|

1.00

(25.4)

|

2.00

(50.8)

|

|

|

|

0.75

(19.05)

|

1.50

(38.1)

|

1.50

(38.1)

|

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

1/8"

(3.18 mm)

|

|

|

|

0.75

(19.05)

|

1.00

(25.4)

|

1.50

(38.1)

|

0.75

(19.05)

|

2.00

(50.8)

|

2.00

(50.8)

|

0.75

(19.05)

|

1.50

(38.1)

|

1.50

(38.1)

|

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

5/32"

3.97 (mm) |

|

|

|

0.75

(19.05)

|

1.00

(25.4)

|

1.50

(38.1)

|

|

|

|

1.00

(25.4)

|

1.50

(38.1)

|

1.50

(38.1)

|

|

|

|

3/16"

4.76 (mm) |

|

|

|

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

0.75

(19.05)

|

1.50

(38.1)

|

2.00

(50.8)

|

1.00

(25.4)

|

1.50

(38.1)

|

1.50

(38.1)

|

|

|

|

1/4"

6.35 (mm) |

|

|

|

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

1.50

(38.1)

|

1.50

(38.1)

|

2.00

(50.8)

|

2.00

(50.8)

|

1.00

(25.4)

|

2.00

(50.8)

|

|

|

|

5/16"

(7.94 mm) |

|

|

|

|

|

|

1.50

(38.1)

|

1.50

(38.1)

|

2.00

(50.8)

|

|

|

|

|

|

|

3/8"

(9.52 mm) |

|

|

|

|

|

|

1.50

(38.1)

|

1.50

(38.1)

|

2.00

(50.8)

|

|

|

|

|

|

|

1/2"

(12.70 mm) |

|

|

|

|

|

|

2.00

(50.8)

|

1.50

(38.1)

|

1.50

(38.1)

|

|

|

|

|

|

|

|

750 Series |

150 Series |

1200 Series |

1350 Series |

2000 Series |

| | Top

Cylinder |

Inside |

Outside |

Top

Cyl. |

In. |

Out. |

Top

Cyl. |

In. |

Out. |

Top

Cyl. |

In. |

Out. |

Top |

In. |

Out. |

1/64"

(.40 mm)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/32"

(.79 mm)

|

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

|

|

|

|

|

|

|

|

|

|

|

|

1/16"

(1.59 mm)

|

0.75

(19.05)

|

1.00

(25.4)

|

1.00

(25.4)

|

|

1.50

(38.1)

|

2.00

(50.8)

|

0.75

(19.05)

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

|

|

|

|

|

|

5/64"

(1.98 mm)

|

0.75

(19.05)

|

0.75

(19.05) |

1.00

(25.4)

|

|

|

|

|

|

|

|

|

|

|

|

|

3/32"

(2.38 mm)

|

0.75

(19.05)

|

0.75

(19.05)

|

1.00

(25.4)

|

0.75

(19.05)

|

1.00

(25.4)

|

1.50

(38.1) |

|

|

|

|

|

|

|

|

|

1/8"

(3.18 mm)

|

1.00

(25.4)

|

0.75

(19.05)

|

1.00

(25.4)

|

0.75

(19.05)

|

1.50

(38.1)

|

1.50

(38.1)

|

0.75

(19.05) |

2.00+

(50.8+)

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

|

|

|

5/32"

3.97 (mm)

|

|

|

|

0.75

(19.05)

|

1.50

(38.1)

|

1.50

(38.1)

|

1.00

(25.4)

|

2.00

(50.8)

|

2.00

(50.8)

|

1.50

(38.1)

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

|

|

|

3/16"

4.76 (mm)

|

|

|

|

1.00

(25.4)

|

1.50

(38.1)

|

1.50

(38.1)

|

1.00

(25.4)

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

1.00

(25.4)

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

|

|

|

1/4"

6.35 (mm)

|

|

|

|

1.50

(38.1)

|

1.50

(38.1)

|

2.00

(50.8)

|

1.50

(38.1)

|

2.00

(50.8)

|

2.00+

(50.8+)

|

1.50

(38.1)

|

2.00

(50.8)

|

2.00+

(50.8+)

|

|

|

|

5/16"

(7.94 mm)

|

|

|

|

|

|

|

|

|

|

1.50

(38.1)

|

2.00

(50.8)

|

2.00+

(50.8+)

|

|

|

|

3/8"

(9.52 mm)

|

|

|

|

|

|

|

|

|

|

1.50

(38.1)

|

2.00

(50.8)

|

2.00+

(50.8+)

|

|

|

|

1/2"

(12.70 mm)

|

|

|

|

|

|

|

|

|

|

2.00

(50.8)

|

2.00

(50.8)

|

2.00+

(50.8+)

|

2.00

(50.8)

|

2.00+ |

2.00+ |

5/8"

(15.87 mm) |

|

|

|

|

|

|

|

|

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

2.00+

(50.8+)

|

2.00

(50.8)

|

2.00

(50.8)

|

2.00+ |

3/4"

(19.05 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

2.00+ |

2.00+ |

2.00+ |

Need help measuring how much edge trim you need for metal sheeting, playground equipment or another project? Easily convert inches to millimeters with our conversion chart conveniently located on the inside front cover of Catalog 700.