3M™ BONDED TAPE SYSTEM BT offers the ultimate bond to the rubber and the ultimate bond to the substrate. It creates a moisture barrier and air-tight seal between rubber and substrate. With the highest peel-and-shear resistance, it can be used under high loads of stress and force. It has low initial tack for easy re-positioning during installation and needs 72 hours of cure time to reach full-bond strength. It has good heat performance from -20F to +158F.

3M™ Heat-Activated Acrylic Foam and Acrylic

Plus Tape

|

|

STANDARD PRESSURE-SENSITIVE ADHESIVE This acrylic-based adhesive is ideal for holding the rubber seal in place while installing in a static application or compressing between two stationary objects. It may be used in some light-duty, dynamic applications against a variety of substrates. It has good heat performance from -20F to +158F.

|

|

| Description |

Rubber seals come in a variety of specially designed shapes made

from custom-formulated EPDM sponge rubber compound. |

| Resistance to |

- Ozone – Excellent

- Water Absorption - Excellent

- Sunlight Aging - Excellent

- Low Temperature – Excellent

- Compression Set - Good

|

| General Temp. Rating |

-20 Degrees to +158 Degrees |

| Compression Rating |

Recommended 25% compression for the maximum performance. |

| Flammability and Code Compliance |

FMVSS 302 (Right Click and Select Save As)

UL50 (Right Click and Select Save As) |

|

This (component or material) is recognized by UL. Representative samples of this component have been evaluated by UL and meet applicable UL requirements. |

| Adhesive Options |

- "BT" Pressure-Sensitive Adhesive: This 3M acrylic automotive-grade tape creates the ultimate bond to the rubber and the ultimate bond to the substrate. It creates a moisture barrier and air-tight seal

between rubber and substrate. With the highest peel-and-shear resistance, it can be used under high loads of stress and force. It has low initial tack for easy re-positioning during installation and needs 72 hours of

cure time to reach full-bond strength. It has good heat performance from -20F to +158F.

- "HT" Pressure-Sensitive Adhesive: This acrylic-based adhesive is best used to hold the rubber seal in place while installing it in a static application or compressing between two stationary objects. It may be used in some light-duty, dynamic applications against a variety of substrates. It has good heat performance from - 20F to +158F. Please note: During application, keep ambient temperature above +60F.

|

Rubber Seal Spec Sheet (Click to Open)

|

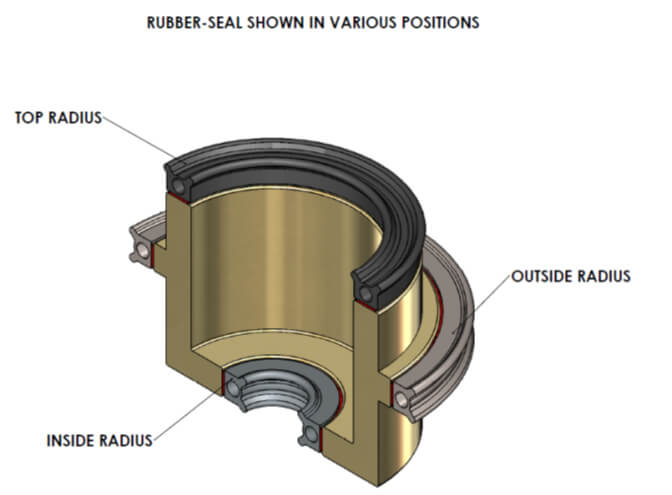

Learn more about our X103BT ribbed self-adhesive rubber seal in the figure below, including top radius, outside radius, and inside radius measurements.

|

| Part Number |

Top Bend Radius |

Inside Bend Radius |

Outside Bend Radius |

| X103BT |

3.00" |

3.50" |

1.00" |

| X103HT |

3.00" |

3.50" |

1.00" |

Watch the video to learn how to measure for, order, and correctly install your ribbed seal. View an installation demonstration at 03:40.

Follow these simple, step-by-step installation recommendations to accurately secure your rubber seals.

Rubber Seal Installation Instructions.pdf